Product

More Than 20 Professional Technicians Service for You

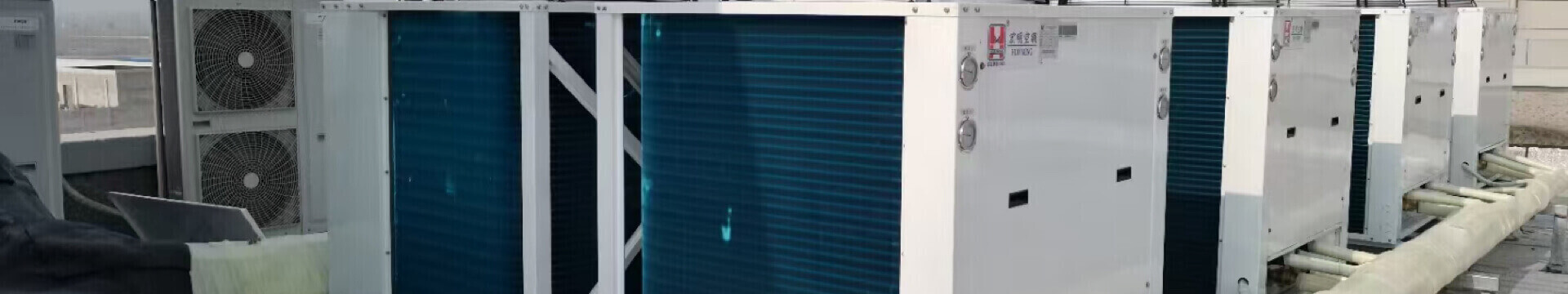

Focusing on the four core pain points of industrial scenarios—"strong corrosion, high dust, flammability and explosiveness, and extreme temperature and humidity"—it is specially designed for harsh environments such as chemical, marine, metallurgical, and pharmaceutical industries. With its all-dimensional anti-corrosion technology, safe and compliant design, and stable and efficient performance, it has become a reliable temperature control solution for extreme environments.

1.Top-tier corrosion protection, adaptable to all corrosive environments.

2.Dual Protection Against Explosions and Compliance, Ensuring Safety Without Blind Spots.

3.Intelligent design and easy maintenance, suitable for modern industrial management.

6.Customized adaptation, covering the needs of all industries.

1. Top-tier corrosion protection, suitable for all corrosive environments

Core components are fully corrosion-resistant: The outer casing is made of 304/316L stainless steel or fiberglass; the heat exchanger is coated with PTFE; the copper pipes are internally threaded and corrosion-resistant; and the electrical terminals are equipped with waterproof and corrosion-resistant connectors.

Optimized structural sealing: The entire unit has an IP65 protection rating, a sealed design, and an independent corrosion-resistant electrical control box, preventing the intrusion of corrosive gases and dust, resulting in a service life more than 5 times that of ordinary air conditioners.

2. Dual Protection Against Explosions and Compliance, Ensuring Safety Without Blind Spots

Explosion-proof Structural Design: Employing multiple protections including flameproof “d” and intrinsically safe “i”, core components such as compressors and fans have built-in explosion-proof devices, eliminating safety risks caused by electrical sparks.

Full-Process Safety Protection: Equipped with overload protection, over-temperature protection, and phase loss protection, the main circuit board is covered with a special protective film, ensuring stable operation in high-humidity and multi-chemical environments.

3. Intelligent and Easy-to-Maintain, Adaptable to Modern Industrial Management

Remote and Convenient Management: Supports WiFi/4G remote control, allowing monitoring of equipment status, parameter adjustment, and receiving fault alarms via mobile app or computer, suitable for unattended operation scenarios.

Modular and Easy-to-Maintain: Modular design of core components; pull-out filter screen can be disassembled and cleaned without tools; reserved maintenance ports + fault self-diagnosis system reduce maintenance difficulty and downtime.

4. Customized Adaptability, Covering All Industry Needs

Multiple Specifications and All-Scenario Coverage: Cooling capacity ranges from 20kW to 500kW, supporting various installation methods such as wall-mounted, floor-standing, and ceiling-mounted, suitable for different scenarios such as control rooms, workshops, and laboratories.

Personalized Customization Solutions: Customized solutions can be tailored to corrosion levels, temperature requirements, and installation space, with optional accessories such as fresh air modules, heating modules, and rainproof canopies.

Specifically designed for harsh environments such as chemical, marine, metallurgical, and pharmaceutical industries.

We receive enquiries in English, Español(Ѕраnіѕh), Русский язык (Ruѕѕіаn), Frаnçаіѕ(French) and ÅL. gadl (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!